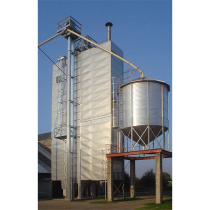

Grain dryers

We offer dryers of the famous German manufacturer Petkus.

PETKUS Continuous Flow Dryers Type DD are designed for drying grain, corn, oilseeds, and free flowing pellets such as clay minerals and straw pellets. Three models (1500, 2500, 4000) with capacities from 8 t/h to 70 t/h (based on wheat and 4% dehydration) are available. The "DD"-series continuous flow dryers use direct heating from oil or gas surface burners.

PETKUS Continuous Flow Dryers Type DDU are designed for drying grain, corn, oilseeds, and free flowing pellets such as clay mineral and straw pellets. Four models (1500, 2500, 4000, 6000) with capacities from 8 t/h to 110 t/h (based on wheat) are available. The continuous flow dryers of the "DDU"-series use direct heating from oil or gas surface burners.

PETKUS Continuous Flow Dryers Type DW are designed for drying grain, corn, oilseeds, and free flowing pellets such such as clay mineral and straw pellets. Three models (1500, 2500, 4000) with a capacity from 8 t/h to 48 t/h (based on wheat) are available. The continuous flow dryers of the "DW"-series are equipped with an efficient stainless steel heat exchanger, which separates the flue gas from the drying air. Alternative heating systems such as steam or hot water heat exchangers are also available on request.

The PETKUS Corn Cob Dryer DHD is used for the energy-efficient drying of husked corncobs at harvest moisture levels. In the Double-Pass Reverse Process all drying chambers are connected with each other by a central air duct system. The hot air is generated centrally by four burners/fans.

The PETKUS Corn Cob Dryer DHS is used for the energy-efficient drying of husked corncobs at harvest moisture levels and is especially suitable for high-quality seed processing. Each drying chamber in the Single-Pass Reverse Process is equipped with a burner and a fan, and can be operated using either upper or lower infeed which allows for gentle and precise drying.

With the PETKUS Fluidized Bed Dryer, design and functionality have once again been successfully combined with efficiency and quality—all captured in one machine. Seed quality is negatively affected when too much moisture is absorbed during or after the coating and pelleting process, which often leads to clumping. Fluctuating weather conditions or high humidity can also lead to high moisture levels that impair seed quality. Without the use of a dryer, seeds can lose their best sowability and grain becomes stale and mouldy during storage. Gentle and efficient drying with the PETKUS DF guarantees that quality seed remains quality seed. The compact zig-zag design not only saves space, but increases flexibility: product can be fed in continuously, in batches, or in semi-batches. Furthermore, the temperature can be controlled at each level.

_210x150.png)