Conveying equipment

We offer the transport technique of german manufacturer PETKUS.

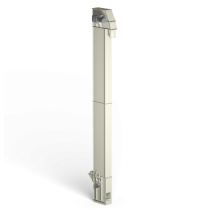

PETKUS bucket elevators are used for the gentle vertical transport of granular and free flowing bulky products, e.g. grain, pulses, oilseed and similar agricultural products. Overall, seven types are available with different bucket volumes, conveying heights and flow rates that can be customized with various motor speeds. Output rates vary between 10 and 400 t / h, tensile strength between 400 and 1000 N/mm and conveying heights between 5 and 40 m.

PETKUS Trough Belt Conveyors can be used in silos, grain storage and malting plants whenever product purity and gentle horizontal conveying are required. Trough belt conveyors can be used for all types of grain, corn, rapeseed, pulses, pellet feed and malt. The conveyor belts equipped with PVC bands are available with a capacity of either 15 or 30 t / h, starting with a loading weight of 0.75 t / m ³. Conveying speed is between 1.0 - 1.5 m/s.

The roller belt conveyors, powered by a gear motor, consist of drive and tensioning stations, inlets and outlets and the troughs with the conveying belt . They offer a low-cost, variable solution for internal horizontal material flow in silos and grain storage while ensuring gentle conveying of the product. PETKUS roller belt conveyers can be used for all types of cereals, corn, oil and pulses and are available in different versions, with capacities between 60 and 150 t / h.

PETKUS Round Bottom Conveyors are used for the gentle horizontal transport of free flowing bulky products, e.g. grain, pulses, oilseed and similar agricultural products. The universally designed conveyor troughs made of galvanized sheet steel can be configured as required. Various types with different trough widths and heights are available, offering output rates between 50 and 100 t/h at a chain speed of up to 0.5 m/s. The maximum conveying length is 50 m.

PETKUS offers flexible and modular trough chain conveyors for seed and grain silos, milling and compound feed systems as well as for malting plants. Dimensions and capacities can be individually assembled and adjusted. Durability is ensured by using hot-dip galvanized sheet steel and alloy chains. Capacities of 50 to 400 t / h with a density of 0.75 t / m ³ are possible for common types of grain at a speed from 0.5 to 0.65 m/s.

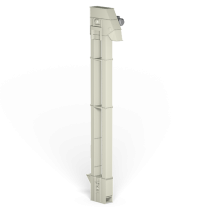

With PETKUS Pendulum bucket elevators, individual conveying routes can be created. Simultaneous vertical and horizontal conveying of granular and free flowing materials can be adjusted in accordance to material and required capacity. Conveying with the Pendulum bucket elevator is segregation-free, break-resistant and dust-free and thus particularly product friendly making it especially suitable for seed.